DC Motor

1. Learning Outcomes

After completing this Section, you will be able to:

- Explain the operating principles of incremental encoders and demonstrate the use of an encoder-equipped DC motor to accurately estimate rotational speed.

- Develop and implement a Simulink model to acquire, process and validate DC motor encoder data for accurate real-time speed estimation.

2. Hardware Set-Up

xxxx

Note that while the ACE-Box can be used for all the exercises, it is not required and only the individual components are needed.

Required hardware for this exercise:

- xxx

Set-up the hardware as shown and following these steps:

- xxxx

Download Now

Download the PDF version of the exercise

3. Simulink Setup and Scope Outputs

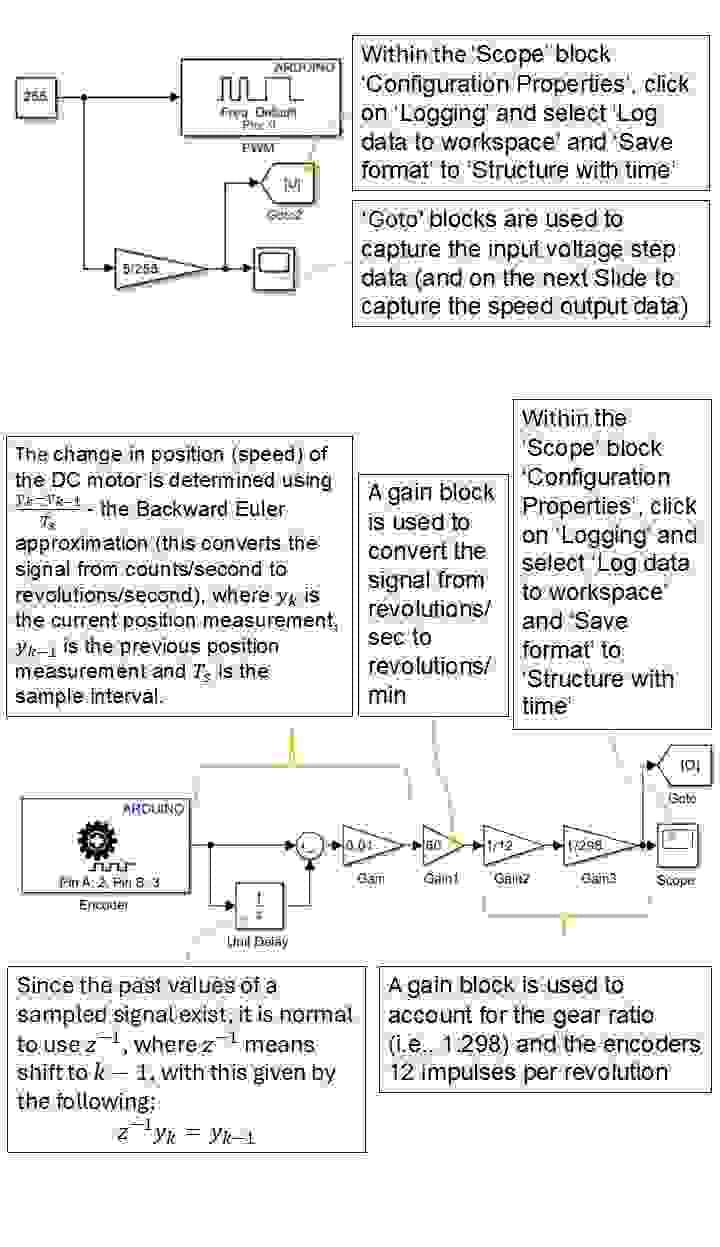

A 5 Volt step input (i.e., value of 255) is applied to pin 9 of the Arduino, see the illustration, with this connected to the DC motor.

In Simulink, the encoder on the DC motor is configured to determine the revolutions per minute (RPM) of the motor. This is achieved by using the encoder counts, which indicate the motor’s position at any given time. By analysing the change in position over a specific sampling interval, the motor’s speed can be calculated. Essentially, the encoder acts as a feedback device, measuring the motor's position in discrete steps. By calculating the rate of change of these steps, the RPM is estimated, providing

a crucial metric for controlling the motor's speed in various applications. The

details of this setup are illustrated in XXXXXXXXXXXXXXXXXXXXXXXXXX

In the illustration below, the four gain blocks are combined into asingle gain block to represent the equivalent mathematical relationship. This is necessary as Simulink requires this format. Additionally, the input voltage Simulink diagram is included because these components need to be ‘Run’ together. A scope has also been added to display the counts per second from the encoder. ‘Goto’ blocks are used in Simulink to capture both the input (voltage) and output (RPM) signals. These signals are then sent to a scope using ‘From’ blocks, allowing the input-output data to be viewed on the scope.

Advancing automatic control engineering (ACE) education through global collaboration